In recent years, the performance of RESURF devices like superjunction have plateaued. The industry universally recognizes the need for better power semiconductors to meet the needs of modern applications ranging from renewable energy to electric vehicles (EVs).

Through engineering and innovation at the atomic level, iDEAL Semiconductor has developed their patented SuperQ™ technology, elevating the efficiency and performance of silicon beyond what has previously been possible and ensuring that this universally understood material will continue to play a significant role in power electronics way into the future.

Fundamentally, SuperQ innovates at the atomic level of power device by implementing greatly improved

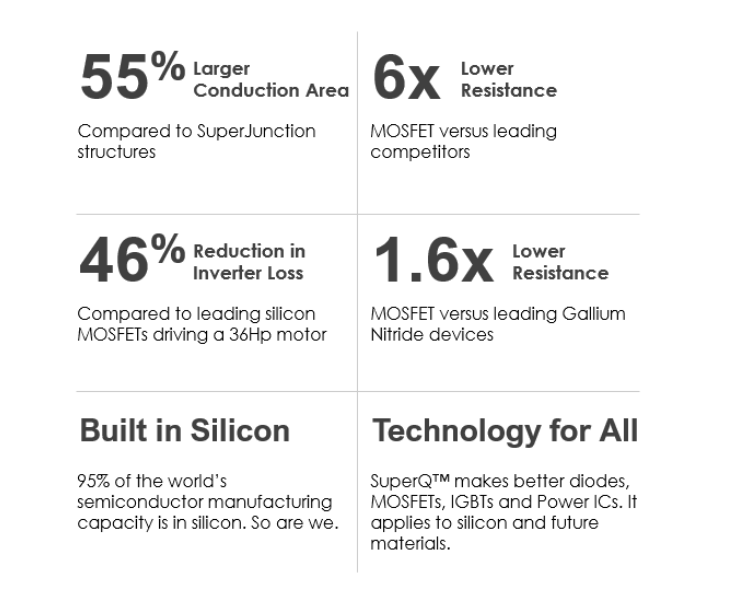

RESURF techniques. The state-of-the-art trench technology delivers near ideal charge balance allowing 50% higher voltage blocking than today’s leading superjunction devices. SuperQ’s asymmetrical trench widens the conduction window up to 95% of the total structure. Combined with thinner epitaxy and higher doping, SuperQ delivers industry-leading performance from 60V up to 850V.

SuperQ techniques can be applied to all power devices including MOSFETs, IGBTs, diodes and power ICs

where it delivers an improved resistance per unit area (R sp ) – showing that SuperQ products can deliver high performance in a small package size. Indeed, the technology delivers the lowest R sp in any available silicon device – up to a six-fold reduction compared to the best silicon products available today. Simply, for any given package, SuperQ will deliver the lowest resistance.

The real benefits of SuperQ technology sit in its performance in real-world applications. Motor drive applications fully leverage SuperQ’s increased conduction area and lower resistance. SuperQ can save up to 46% of inverter losses, which are typically dominated by conduction.

However, SuperQ is not just optimized for low conduction loss. Products designed with SuperQ technology have ultra-low leakage current, store less energy, and exhibit lower reverse recovery. These products are ideal for hard commutation, outperforming even today’s fast recovery devices.

SuperQ is built using a CMOS-like process that is suitable for 200 mm and 300 mm wafers. As a result, it is fabricated using tools and processes that are commonly found in existing silicon fabs. Combining SuperQ’s ability to improve resistance to market-leading levels with silicon’s decades of proven reliability, manufacturability, and availability, the new technology brings a renaissance to silicon power.